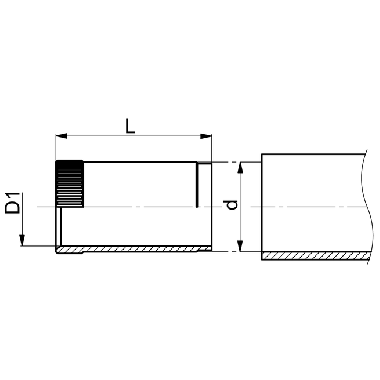

| Type | (Cust.) Art. no. | D1 | d | L | CAD | Legend | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | VHS-04 | Art. no. | 706.0030.059 | D1 | 2.5 mm | d | 4.0 mm | L | 15.5 mm | CAD | Download | |

| Type | VHS-05 | Art. no. | 706.0030.056 | D1 | 3.5 mm | d | 5.0 mm | L | 15.5 mm | CAD | Download | |

| Type | VHS-06 | Art. no. | 706.0030.080 | D1 | 4.5 mm | d | 6.0 mm | L | 15.5 mm | CAD | Download | |

| Type | VHS-07 | Art. no. | 706.0030.105 | D1 | 5.5 mm | d | 7.0 mm | L | 17.0 mm | CAD | Download | |

| Type | VHS-08 | Art. no. | 706.0030.103 | D1 | 6.5 mm | d | 8.0 mm | L | 17.0 mm | CAD | Download | |

| Type | VHS-09 | Art. no. | 706.0030.122 | D1 | 7.5 mm | d | 9.0 mm | L | 17.0 mm | CAD | Download | |

| Type | VHS-10 | Art. no. | 706.0030.121 | D1 | 8.5 mm | d | 10.0 mm | L | 17.0 mm | CAD | Download | |

| Type | VHS-11 | Art. no. | 706.0030.144 | D1 | 9.5 mm | d | 11.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-12 | Art. no. | 706.0030.154 | D1 | 10.0 mm | d | 12.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-13 | Art. no. | 706.0030.153 | D1 | 11.5 mm | d | 13.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-14 | Art. no. | 706.0030.165 | D1 | 12.0 mm | d | 14.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-15 | Art. no. | 706.0030.181 | D1 | 13.0 mm | d | 15.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-16 | Art. no. | 706.0030.185 | D1 | 14.0 mm | d | 16.0 mm | L | 22.0 mm | CAD | Download | |

| Type | VHS-17 | Art. no. | 706.0030.207 | D1 | 15.0 mm | d | 17.0 mm | L | 22.0 mm | CAD | Download | |

| Type | VHS-18 | Art. no. | 706.0030.206 | D1 | 16.0 mm | d | 18.0 mm | L | 22.0 mm | CAD | Download | |

| Type | VHS-19 | Art. no. | 706.0030.225 | D1 | 17.0 mm | d | 19.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-20 | Art. no. | 706.0030.224 | D1 | 18.0 mm | d | 20.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-21 | Art. no. | 706.0030.210 | D1 | 19.0 mm | d | 21.0 mm | L | 21.5 mm | CAD | Download | |

| Type | VHS-22 | Art. no. | 706.0030.252 | D1 | 20.0 mm | d | 22.0 mm | L | 24.0 mm | CAD | Download | |

| Type | VHS-24 | Art. no. | 706.0030.285 | D1 | 22.0 mm | d | 24.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-25 | Art. no. | 706.0030.284 | D1 | 23.0 mm | d | 25.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-31 | Art. no. | 706.0030.355 | D1 | 28.5 mm | d | 31.0 mm | L | 18.0 mm | CAD | Download | |

| Type | VHS-32 | Art. no. | 706.0030.320 | D1 | 29.5 mm | d | 32.0 mm | L | 23.0 mm | CAD | Download | |

| Type | VHS-33 | Art. no. | 706.0030.354 | D1 | 30.0 mm | d | 33.0 mm | L | 23.0 mm | CAD | Download | |

| Type | VHS-38 | Art. no. | 706.0030.996 | D1 | 35.5 mm | d | 38.0 mm | L | 24.0 mm | CAD | Download |

Reinforcing sleeves

for thin-walled tubes

SO Code:

-

Art. no.: -

Technical details

Additional information

Assembly:

Insert sleeve into tube up to the knurled edge. Use a hammer (plastic or hard rubber) to drive in the sleeve all the way. This will cause the knurled neck to be pressed into the inner wall of the tube and will secure the neck against being dislocated or falling out.

Information on which tube is recommended for use with reinforcing sleeves can be found in Section i under “Recommendations for stainless steel tubes”.

Insert sleeve into tube up to the knurled edge. Use a hammer (plastic or hard rubber) to drive in the sleeve all the way. This will cause the knurled neck to be pressed into the inner wall of the tube and will secure the neck against being dislocated or falling out.

Information on which tube is recommended for use with reinforcing sleeves can be found in Section i under “Recommendations for stainless steel tubes”.

Assembly:

Insert sleeve into tube up to the knurled edge. Use a hammer (plastic or hard rubber) to drive in the sleeve all the way. This will cause the knurled neck to be pressed into the inner wall of the tube and will secure the neck against being dislocated or falling out.

Information on which tube is recommended for use with reinforcing sleeves can be found in Section i under “Recommendations for stainless steel tubes”.

Insert sleeve into tube up to the knurled edge. Use a hammer (plastic or hard rubber) to drive in the sleeve all the way. This will cause the knurled neck to be pressed into the inner wall of the tube and will secure the neck against being dislocated or falling out.

Information on which tube is recommended for use with reinforcing sleeves can be found in Section i under “Recommendations for stainless steel tubes”.